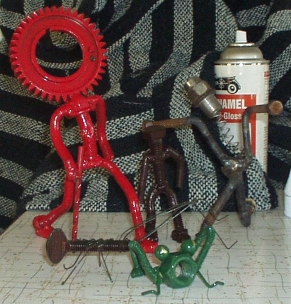

parts-is-parts

the manual calls this, or at least part of it, the #2 clutch hub. It seems to be binding. Makes sense, since the transmission didn't like going in or out of 2nd.

I know new gears are out of the question, so i filed the obviously worn sections to make it slide smoothly.

The other hubs appear to slide freely.

4/01

The shift rods are a bit wobbly in the center housing, which could make the shifting want to bind. There isn't much i can do about it at this point.

At least I'm running out of parts to put back together.

4/02

Down to just one big part. Finding places for all the little parts was rather tedious, but I managed, thanks to some service manual excerpts and pictures i found online.

It seems everything about this trans wants to make shifting a chore. The main shift rod wants to bind in and out of 2nd, 4th, and reverse. The rear case didn't even want to go on without binding that rod up, but once i recognized the hold-up, i got it to slip on smoothly. Then it seemed to shift fine until i got the bolts all torqued. i might take the housing back off and enlarge that rear shift rod hole a tad and pack it with grease. Once I torqued the bolts and levered it into 2nd, the rod actually took a small chip out of the aluminum at the rear alignment hole. Something is bent, i fear. Either it's the rod itself, or something is off kilter in the rear housing. No more money is going into this trans. Personally, I think the Suprang is better suited to an automatic trans anyway ;)

At least I learned how not to rebuild a trans. Next one needs its own dirt free room, with lots of tables and room to move around whilst working. I tried to keep it clean, but there was a period of time while i had many of the parts supposedly covered while waiting for the right tools to get a gear off. The covering didn't work as well as I'd hoped it would, but it was covered in a fine layer of filth which otherwise would have all been in the trans. There was a lot of cutting and welding going on all around them :(